Update 20/05/2022

I tested the drive train again after keeping the set built for a long time, and also tried if the new improved gears could help getting rid of the cracking:

Unfortunately the new gears did not solve the situation either, so I have to say that despite the most careful assembly, the set will start to show the cracking behavior sooner or later.

Introduction

I shared many videos with you about the LEGO Technic Land Rover Defender already, you saw my detailed building review, the details of the drive train and the one about the cracking noise and the possible fixes. I received hundreds of comments from you and many-many requests for help, hopefully in most of the cases I was able to assist to find the proper solution.

I decided to create a summary and a video about all the potential issues I found during the building process. I’ll also go through the drive train from the wheels to the engine, how to verify your build, and what are the problems that are not really problems. Each section is linked to the proper part of the video, use the summery below to find the section you are looking for:

- Introduction

- Drive train walk trough, how does it work

- Body removal guide

- Building errors based on steps

- Step 4 – rear differential direction swap

- Step 45 – gears swapped or not placed correctly

- Step 65 – small cross block inserted incorrectly

- Step 74 – small cross block inserted incorrectly

- Step 84 – small cross block inserted incorrectly

- Step 88-89 – U-joint orientation

- Step 102 – Red 2L axle

- Step 104-106 – rear suspension – lower attachment point of the springs

- Step 134 – front differential direction swap

- Step 152 – front suspension – lower attachment point of the springs

- Step 259-261 – correct assembly of the DNR and Hi/Lo selectors

- Building errors based on the symptoms

- Cannot connect the two assemblies properly at step 62

- Rear wheels are blocked when the car is pushed forward – mistake at step 65

- Gears does not fit properly at step 45

- All wheels are blocked when turned together – possible issue at step 84

- Front and rear wheels turn against each other when the central differential is manually turned – differential direction swap at the front or at the rear

- Gearbox and fake engine does not work at all – possible differential direction swap at the front or at the rear

- Cracking noise in the drive train – U joints not aligned properly at step 88-89 or U joint touches the 24 tooth gear at step 272

- Suspension seems to be soft, the front axle or the rear axle of the car sits down

- Verification steps

- General advises

- Problems that are not really problems

- What to do if everything is built correctly and the gears are still cracking

Drive train walk trough, how does it work

I go through the drive train from the wheels up to the engine to demonstrate how it works. I suggest to watch it to have a better understanding on the mechanism, it helps to find the issue with your build.

Body removal guide

This section shows you how to remove the body of the car in bigger pieces to gain access to the internals

Building errors based on steps

Step 3 – incorrect gear used, issue at step 62

Error: a 12 tooth black gear is used at step 3 instead of the 8 tooth dark bluish gray gear

Symptom: the two assemblies cannot be properly joined at step 62, the axle won’t turn

Step 4 – rear differential direction swap

Error: The orientation of the differential is important at step 4

Symptom: If one of the two differentials is built in reversed then the front and rear wheels will work against each other and the central differential won’t turn, it won’t drive the gearbox and the engine. Click here to see how does it look like.

How to fix with a finished build : Follow these instructions:

Step 45 – gears swapped or not placed correctly

Error: If incorrect gears are used at step 45 then the assembly cannot be completed

Step 65 – small cross block inserted incorrectly

Error: a common mistake that can be made a lot of times in this build. If the #6536 Technic cross block is inserted incorrectly then the axle that supposed to turn freely in the pin hole will be blocked in the axle hole.

Symptom: The rear wheels does not turn when the car is pushed on the ground as the output of the rear differential is blocked

How to fix with a finished build : Follow these instructions:

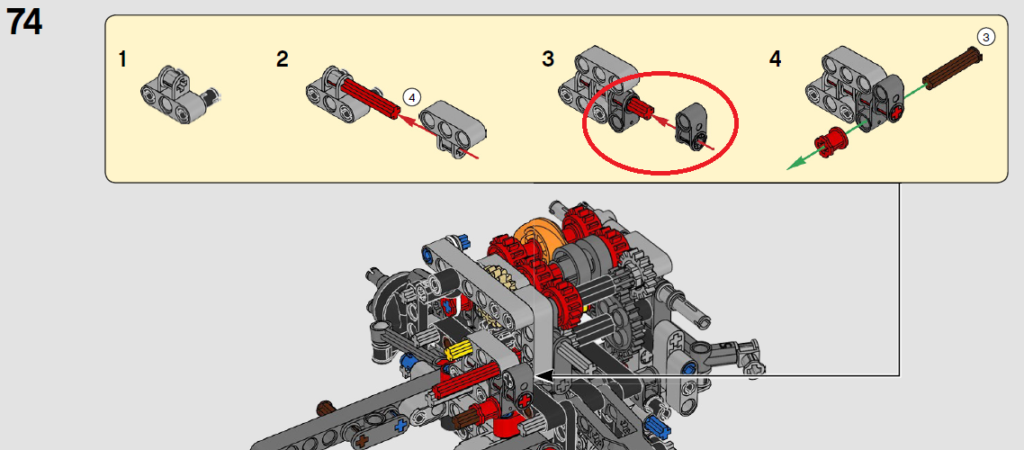

Step 74 – small cross block inserted incorrectly

Error: a common mistake that can be made a lot of times in this build. If the #6536 Technic cross block is inserted incorrectly then the axle that supposed to turn freely in the pin hole will be blocked in the axle hole.

Symptom: The central differential or the gearbox is blocked

Step 84 – small cross block inserted incorrectly

Error: a common mistake that can be made a lot of times in this build. If the #6536 Technic cross block is inserted incorrectly then the axle that supposed to turn freely in the pin hole will be blocked in the axle hole.

Symptom: The central differential is blocked

Step 88-89 – U-joint orientation

Error: if the universal joints on the input and output shafts of the gearbox are not aligned correctly

Symptom: the drive train will not run smoothly and in higher gears you’ll hear a cracking noise.

How to fix with a finished build: Follow these steps:

Step 102 – Red 2L axle

Error: if the 2L red axle is not pushed in then the some beams will not be linked together and the structure becomes unstable

Step 104-106 – rear suspension – lower attachment point of the springs

Error: The lower attachment point of the springs in the rear suspension are chosen incorrectly, the inner hole is used on the suspension arm instead of the outer axle hole

Symptom: the suspension will not work properly and the whole rear of the car will sit lower than the front

How to fix with a finished build: follow these steps:

Step 134 – front differential direction swap

Error: The direction of the differential is important at step 134

Symptom: If one of the two differentials is built in reversed then the front and rear wheels will work against each other and the central differential won’t turn, it won’t drive the gearbox and the engine.

How to fix with a finished build : Same as the fix for Step 4

Step 152-154 – front suspension – lower attachment point of the springs

Error: The lower attachment point of the springs in the front suspension are chosen incorrectly, the inner hole is used on the suspension arm instead of the outer axle hole

Symptom: the suspension will not work properly and the whole front of the car will sit lower than the rear

How to fix with a finished build : Same as the fix for Step 104-106

Step 259-261 – correct assembly of the DNR and Hi/Lo selectors

Error: the assembly of the DNR and the Hi/Lo selector requires a lot of parts to be aligned correctly, if there’s a mistake they won’t work properly

Step 271 – correct gear usage

Error – if the dark bluish gray 8 tooth gear is not added at step 271 or an incorrect one is used then the front wheels won’t drive the central differential

Symptom: The front wheels are not driving the central differential

Step 272 – U joint should not touch the 24 tooth gear

Error: The U-joint on the input shaft of the gearbox is placed incorrectly and it touches the 24 tooth gear next to it

Symptom: Cracking noise coming from the drive train

How to fix with a finished build: Follow these steps:

Verification steps

I suggest to follow these verification steps to see if everything works correctly at that stage.

What shall work at the end of bag 1 at step 123

Verification of all functions at step 321

General advises

- There should be no bigger pieces or gears left after any building stages. You can see the list of the leftover parts here at the end of the inventory. If you have any bigger parts left after finishing a section go back and find where it belongs.

Problems that are not really problems

Left/right or front/rear wheels are turning in the opposite direction

Step 62 – wheels are not turning the gears in the gearbox

At this stage the wheels are not yet connected to the gearbox

End of bag 1 – wheels are not turning the gears in the gearbox

At this stage the wheels are not yet connected to the gearbox

What to do if everything is built correctly and the gears are still cracking

As you see in the video, if the car is still cracking then the best solution is to take it apart and try to rebuild it with everything aligned properly. There’s no ultimate fix for the cracking, you need to verify each section carefully to ensure a smooth operation.

There is one additional thing you can try to fix the cracking if everything else fails, although this falls in the “might or might not work” category. For some people flipping both differentials at the front and rear axle eliminates the cracking.

Haven’t got this set yet?

Check out here…

Choose your local online LEGO Store below to get the LEGO Technic 42110 Land Rover Defender.

lego.com US / lego.com UK / lego.com AU

Disclaimer: the post contains affiliate links, they won’t cost you extra money but any purchase made through them might help to run the site with a small commission.

Fantastic, job well done, Thanks a million !

My central differential (red thing) is stuck. Please help me

I suggest to follow the troubleshooting steps in the article

The pistons do not move up and down when I roll the car. Am I setting the shifting properly?

I’m having the same problem. Strange thing is when you hold the model holding 3 wheels and also not hold 3 wheels and spin one wheel, guess what it moves the pistons. I cannot find any fault, I’ve gone over the entire linkage systems and can’t find a fault.

Try to rotate the central differential manually and see what happens. Your wheels should all rotate in the same direction, if they don’t then you might have one of the differentials (front/rear) in the wrong direction.

Hi! My car is only making crackling noises when the highest gear (4) is in use… It runs smooth on all the lower gears (1-3). What can I do to solve that kind of problem? Any suggestions?

Me too

Question after bag two with the wheel on car moves free but the engine dosent move when pushed along and can’t work it out

Put the car on its side stop any 3 wheels and then turn the 4th the engine turns

Please help

You can rotate the central differential manually to see if all wheels turn to the same direction. If not then check the orientation of the front and rear differentials

Check all potential issues, if no solution then dismantle, rebuild, verify each phase during build.

Same 🙁 but if I roll the wheels slowly without rapid movements cracking noise disappeares. So it might be just the friction

Did you manage to fix the clicking in high gear? I’ve re built the whole car following all of the above steps and still have the same problem?

Try rolling the car backwards (and not forward), but still on D. Does it work that way and doesn’t crack? If that’s the case, flip both the front and rear differentials so their large side is facing the passenger side of the car.

Wow, thank you so much that actually worked

As far as I understand, there are two gears that are offset to each other (one that comes from the differentials and one that is connected to the DNR gears) which have a better grip on each other on this specific rotation direction. Flipping both differentials effectively swaps their rotation direction.

^^^ This fixed our build as well. Many thanks!!!

This comment is the one! You’ve just spared me from driving myself nuts! Thankyou!

como se llama el programa que utiliza para simular en 3D y utra pregunta la transmision truena mucho podria agregarle un poko de aceite de maquina de coser …

saludos excelente su perfil

Don’t put oil in it, it’ll ruin your build. The 3d program is LDCad – http://www.melkert.net/LDCad

Pingback: LEGO Technic: Guida di riparazione per il Land Rover Defender (42110) - Hobbymedia

Um… I did everything but it is still cracking and my car is bought in new less than a week, so someone please help me for the annoying cracking from my new car.

I’ve often found that newer LEGO sets gears have more friction, as they get used they wear down and run more smoothly. Run it a lot, disassemble it if you have to, but over time the gears should run smoothly.

I’ve built my model but when I turn the red diff (in front of the grey one) all the wheels turn, however when I turn the front or rear diff only the respective diffs turn up to the centre diff. My engine does not operate only when I turn the cog in the boot Also I don’t think my gearbox/hi-Lo or +\- fines done seem to do anything thing??

I’m struggling to get the pistons to move.

I’ve followed the guide posted above it all appears to be in order but yet, the pistons will not go up and down when the car moves.

Does anyone have any idea?

Remove the body, put the car in D, then follow the guide that shows how the drive train works from the wheels until the engine. If something does not move as it is supposed to move, you’ll find the source of the problem.

Hi! I like this a lot but I must have Done something Wrong I cant steer my front Wheeling Will not turn.

Hi, I had the same issue and went back. In my case, one of the small pins in number 132 was upside down. For both, the top level should be equal to the brick, the very small part that sticks out should be at the bottom.

Hello, I too have encountered this scenario. Is there a way to reposition the tiny gray piece upside down without disassembling the entire thing?

Hi, love the guide but I’m still having issues. I can only get the pistons to work when in R. I’ve rebuilt the whole gearbox several times but cannot get it to work in D.

Please help

Thanks

If it does work in R but not in D then check the Hi/Lo selector and the gearbox itself. Does the input shaft of the gearbox rotate when you push the car? Does the output shaft rotate? You can narrow down the issue if you have a look at my video, understand what parts should be engaged when it’s in D and compare it to your build.

Did you manage to fix this issue? I’m having the exact same issue works fine in R but if try to run in D will go so far and then will run backward when I pick it up. Its so frustrating and I really don’t want to have to take to bits again.

Hi mate did you find out what the issue is I’m having the same dam problem. Works in R but like binds fights against each other in D when u pick it up it’s like a wind up car.

The U Joints are placed correctly,the red diferencial cracks in Most Gears and the engine doesnt works good.

Please Help me.

My problem was not listed. Both the rear wheels are incapable of moving in the same direction and the entire rear gearbox is wont move and will make the cracking sounds if forced. I think the problem is that there is a gear that is stuck in the back, but I was wondering if this was a more common problem.

Check the video which axles and gears should be able to rotate and verify them in your build

Had the same issue. The gray piece that the axl goes into was in wrong which did not allow the gear to move at all.

Very helpful guide. Thanks ! After going through the steps I’m left with a strange issue. I get cracking noises only in 1st and 2nd gears (both Hi and Lo). Is this a known/fixable issue ?

Thanks

The cracking is quite difficult to eliminate fully, you need to have every gear/axle and piece aligned without adding extra tension to the drive train.

Is it possible that in the newest production run some of the manual issues have been resolved?

The mistake with the U-joint alignment was corrected already some time ago in both the printed and the online manuals, I’m not sure if there’s anything else to correct.

I’m sorry, I misunderstood what these errors are; they’re common mistakes, not errors in the manual. Thank you for clarifying, and even more for putting all of this together!

When in gear, my front and back wheels spin against each other… all differentials appear to be in the correct orientations (the larger end of the differentials are both along the left side of the car).. tried doing a rebuild of bags 1 and 2… still no luck..

Any suggestions to try??

My front and rear wheels spin against each other when in drive… all differentials appear to be in correct orientations…. I noticed when I spin the small grey gear that connects far right side u connector with the gears that move the pistons, manually, the wheels spin correctly…

Please help!?!?

Hi, I love this site. Thanks for sharing this info. I figured out one of the problems I had. But, I have a big question remaining. The gear in my car works if I pull the shifts, but nothing happend and also the motor ins’t running. https://youtu.be/Qz8FYlMixQI

Can you help? Hoping to hear from you.

Joris

Did you check the differentials?

I fixed some clacking due to u joint connections hitting gears. Thanks.

But in the highest gear, or lowest – I can’t tell – the car acts like pull back wind up toy. Either the pistons do nothing and then go in a fast burst. Or if I push the vehicle and then lift the wheels they unwind in the opposite direction! 🙁 In other gears it’s ok.

Differential orientation is correct and my u joints are aligned thanks to you. Any thoughts?

Hi Douglas, I have same issue with engine and gears not moving much and then running really fast. Also if you push the car forwards it then starts to run backwards! Did you find the cause ? About to go for a rebuild here. Thanks

Hi Jim, I have the same issue here. Have you managed to solve it?

I really enjoyed watching the whole video, thank you very much for putting it together!

Thank you for this guide !

Step 88-89 above fixed the cracking noise. Good thing it was an easy fix, just had to remove 1 seat and 1 door.

Do you have any videos for building steps 206-246, I’m on my third go building this section and every time I connect everything up the engine does nothing when I move the various cogs. The selectors appear to be in the right position but they don’t do anything in terms of engaging different gears.

Also on my fifth go of trying to make the wheels all go in the same direction as each other. I own more than twenty bits of Lego technic and no kit has flummoxed me like this ! Almost getting to the point where I’m not enjoying it.

I only have the video that you see in this post. Try to follow the drive train from the wheels from the central differential and see which gears are engaged.

Thanks, I’ll try again. I’m a Lego enthusiast not an engineer or a mechanic, I think for this build you need to be the latter. I’m obviously making the same mistake every time because the instructions aren’t clear enough to me as a non-mechanic.

Slightly different problem for me. It runs okay in reverse in lowest gear (i.e. engine turning over fastest), but clicks when pushed forward. Does anyone have any ideas?

I should clarify when I say ‘reverse’ I mean pushing it backwards. The gear selector is in ‘D’ in both circumstances.

Fantastic! That’s not cracking anymore! Thanks for all. You’r the best!!

i have the mistake instructions in step 89 the u joints are wrong position but you help guide help me a lot i build this set like you after 2 bags (number one and number 2) i put wheels on land rover and test if anything works wrong and everything was correct thanks you help guide i build land rover complety today and everything works smooth if you hadnt made these videos i would be in trouble like step 89 im maybe could have built wrong

i have two problems. i have the shifter on D, at 1st or 2nd gear it’s ok bot on 3rd and 4th i hear the carcking noise. if the shifter is on R then all the gears (1-4) are ok. the other problem is that if i steer the wheels at the roof then it feels a little bit hard to steer but if i steer on the steering wheel inside the car or if i steer the wheels from the actual wheels it feels even more harder. Can you help please?

Sorry for my bad english.

I am not sure the order of the 4 gears is correct. In the sense that they don’t go from faster to slower as I rotate the selector, they seem in some random order. Could you please double check on your and tell me how the orange gear selector is positioned when the lower (-) gear is selected? Thanks!

I have the same problem but only in D mode. Everything is checked and still no results.

Really appreciate the effort going into this blog and the videos. Very helpful! I watched it prior to my full rebuild of the model and it helped me in avoiding the U-joint mistake.

My situation is that I have no cracking noise as which is caused by the mis-aligned U-joints. Also no cases of the wheel turning backwards once you pick it up. All gears are working and the fake engine is moving. So basically I think I have the build correct. However, I do find the resistance that the model has in High gear a bit unpleasant. More specifically only in D/Hi/2 and D/Hi/3 you notice that the output shaft is playing catchup sometimes and thereś just more stress on the drivetrain as I would like. (I am unable to make it crack, even when driving it very quickly) I would still want/desire a more smooth/fluid experience but I am at a point of believing it is simply not possible to get everything running buttery smooth on this model. (I think this is also what RacingBrick indicates in his videos).

@RacingBrick: at those moments when you demo what sounds “normal”, dropping the music would be helpful! 😀

– Gearbox alone is smooth (ratating in and out shafts)

– Fake engine is smooth (when using R)

– DNR and Hi/Lo selector is smooth

> Just when everything is together with those high gears…

Maybe it’s time to let it rest and just build the body of the car.

I think this is pretty much the maximum you can achieve, it will not be smoother than that. Just take a look at all the plastic gears working together (with their tolerance rate) and you will understand why it works like this. To make it better a drastic simplification would be needed.

Yes, I think you’re right. But it sure feels nice having you confirm that once again. 😉 Thanks again for all your efforts, really enjoy your content!

Edit: I meant D/Hi/3 and D/Hi/4 of course.

I just finished my build….. I was so happy! And then I realized something was very wrong. At step 75 I had missed one of the cogs on the central differential (the one that sits on the grey axel).

What is the easiest way to get to the differential to install the missing cog?

I had the problem – no freewheel in any gear – and revisited step 65, inverted the piece and now freewheels – but freewheels in F & R as well as N, and no engine movement!!

How bad id this?

My son put together this model, and the pistons wouldn’t move. Without much hope, I went through your guide, and much to my surprise, you actually described the problem: the differential from step #4 was mounted in the wrong direction! After changing it, it now all works as expected! Thanks a lot – really! You made our day in the quarantine 🙂

I’m really glad I could help 🙂

been trying to fix now for 4 hours or more

i have perfect sync in reverse, pistons work, drives smooth

but in forward does not want to drive and springs back.

tried so many times lost count inc changing both diff.

in forward gear red central diff really struggles in forward

help

There should be a connection that is slightly misaligned. Unfortunately there’s no exact simple solution for this, you either accept it as it is or rebuild with frequent verifications.

Hi Everyone,

I’m hoping to get some advice regards to steering.

I’ve just finished building the model, and the steering doesn’t work at all.

I’ve taken it apart and rebuilt and I still can’t get the steering to work. It must be something really simple. 🤯🤯

Any Advice would be grateful.

Remove the body according to the instructions here and follow all gears from the HOG steering to the steering rack, you should be able to find the issue

i have this model and it has been sat in its box for about a month, before then first opened and built. I have checked it on the videos above and it still cracks. It has a steady rise in stiffness before getting smoother but quickly after it peaks at a higher point of stiffness. It does this 1 or 2 more times before continually cracking. the Lower gear it is on the quicker and worse the cracking comes on (with gear 1 being almost instant). Should i try and run it to make the gears wear in or do something else?

Rebuilding it with careful alignment of all the parts is probably the only way to do it.

So my model’s only problem is the higher the gear I set it to the more likely it seems the gears pause and lag and then will turn the other way like a wind up toy. I’ve looked over the other comments and it seems this is a common enough problem where the wheels will spring back once I pick it up if it was struggling along. The pistons will pause and then move really fast. I just rebuilt the front gearbox which fixed my cracking problems so I’m wondering if what I should do is rebuild the back gearbox? Just confirming there isn’t another easy course of action and that that is what I should do. Thanks.

This is the same effect that causes the cracking, apart from the fixes described here the only solution is to rebuild the drive train carefully.

Also, unrelated question, should the pistons move in D if neither Hi or Lo gear are selected and the red selector thing is just in the middle? Because mine do not.

The selector should be in either hi or lo, otherwise the gears are not engaged

Thanks a lot man, for real, you’re really dedicated to helping us out!

hey guys, i need advice

my red differential is cracking even though the u joints are corrected, this happens when its set it to drive at high on the highest gearbox setting.

Totally the same with me.

Hello! I cannot get my dang car to work! I have had no luck getting my pistons to work. I noticed that the shorter u join is hard to move and it’s stopping the car from working. And advice???

I still haven’t gotten it I am pretty sure it’s the short U joint because both parts were working fine until they were joined together and it’s like the short u joint is jammed

Same here!

Everything seems running nice and smoothly and after connection the only reward is cracking and cheap pullback-car behavior…

It really drives me crazy!!!

I’m a really experienced Lego Technic Builder and I was really looking forward having the Landy…

But now I’m really considering sending it back as broken and asking refund…

Sooo saaad…!!!

Step 65 saved me about 30 hours.

Fantastic job mate!

Dear community,

I have a big problem with my Defender!!

I already did Racingbricks repair-guide step by step! I even disassembled everything and rebuild it from scratch, doublechecking all steps, aligning all axles and gears carefully and taking the greatest of care that all gears could turn easily!

(And I’m really a experienced Lego Technic builder!!)

But in the higher speeds, my Landy behaves always as a cheap windup car! (As described by others before me!

It’s been sooo long I was looking forward to have this model!!

But now that I have it, all I have is biiig frustration and disappointment!!!

Any tips would be HIGHLY appreciated, thanx!!

I had the clicking sound and applied the differential flip trick and fixed my issue. My individual gear pieces were functioning perfectly while the connected body always had an issue. Flipping fixed it.

I know it says up there may or not may fix it but I am posting to note that I am another positive outcome. So with high probability this may work for you as well.

Both my differentials do not work and when I turn the drivesshaft, only the front wheels will turn.

The large grey piece of the differential turns when I turn any wheels. Only 2 of the small internal beige pieces turn when I spin and individual wheel on any side. When I spin the driveshaft, the front wheels turn fine, but the back wheels do not turn. All rotation stops after the main structure of the central differential. Both grey differentials worked just fine before assembly at step 321. On my first build I did not have this issue, I had cracking which I solved with my rebuild but now these issues remain. I had to rebuild up to step 123 about 5 times for the rear differentials to work properly and all of a sudden it stopped working.

Check the orientation of the differentials, whether they are not working against each other. If you turn the central differential manually then all wheels should turn in the same direction.

When the vehicle is in drive I push the vehicle forward and the cylinders are not moving can you help me please what should I do

I certain gears you need to push almost 1m to engage the engine. If it does not move at all then check my video section by section, how the drive train supposed to work and compare with your build.

The vehicle is moving way easier when I push it backwards is it supposed to be LIke this

I have a problem being the engine runs when pushing the car forward and backwards when reverse gear is selected… other than that I’m sure everything works fine just not sure what to change to fix this issue

Please help, much appreciated

Not sure if I get the problem, the engine should run when reverse is selected. Can you explain it better?

Sorry, when reverse is selected the engine moves both when rolling the car forwards and when I push the car backwards.

The car does not know when you push the car forwards or backwards so it won’t have an effect on the engine. Reverse here means 2 things – the engine itself runs “backwards” compared to the forward gears, and it has a constant speed so the gearbox is bypassed.

Cheers mate I appreciate it

Will you make instructions on how to motorize this fantastic Lego set?

I don’t think so, there are a lot of instructions already for this one

Flipping both differentials on front and rear axle immediately solved the cracking problem in the higher gears

Thank you.

I thought I had followed all the steps up to 70 in phase 1 correctly but when I roll the left or right wheel, the other wheel will only go in the opposite direction. Effectively, the wheels go in opposite directions from each other.

I suggest to take a look at the sections that explain how differentials work, this is perfectly normal

Hello!

I just finished step 398, and I put the wheels on to test it, but when I tried pushing the car forward, the fake engine pistons did not move. This happens when I push the car backward too. I tried all the gear options and it doesn’t move.

nevermind, the differentials were not positioned right

the back wheels are also going in the opposite direction

Fantastic job, thank you. I was going crazy and about to pull the set apart and start again but you saved me!

My gearbox moves on reverse but it doesn’t move on drive is there any fix for this?

Step 65 totally got me and my 9 year old son in this build. Was racking my brain trying to figure out why the back wheels were locked up. Your description of various problems and solutions were great and easy to follow! Thanks for the info!

Habt ihr das auch vielleicht für mich als PDF Datei

Hi, I have got past step 321 and noticed I’ve used the wrong gear at step 62 😒 any tips on how to change the gear without dismantling the entire thing 🤔

I reviewed all the actions, everything was done correctly, but still, when the car is rolling forward, a crack appears and if it is released at this time, it will go back by itself, as if on a spring

This is a great site, it should exist for every lego set.

I found this site too late. I have rebuild my defender 3 times before I had it correct.

Thanks for making these notes and films.

I hope to find more of these in the future.

I’m glad it was useful for you. I really hope not many other LEGO sets need this kind of troubleshooting guide 🙂

I have an issue and it’s not listed here, maybe you can help.

If I manually turn the center diff all 4 wheels turn in the same direction (forward or backwards).

If I turn the shaft coming from the front wheels the back wheels do not turn.

If I turn only the front/rear wheels the other 2 wheels don’t turn.

So it seems I don’t have 4×4. Any idea what it might be? (as I said, if I manually turn

the center diff all 4 wheels turn)

That’s normal. If you turn the shaft coming from the front wheels, then they will drive the fake engine through the differential. You need to hold the red central differential housing in place manually and turn the shaft coming from the front wheels to drive the rear wheels.

Ohh okay, so what you are saying is that it’s a4x4

Only if the engine is providing the power.

So if a were to attach a real engine instead of the fake one it

so that’s what is powring the center diff then it will be 4×4.

Thanks so much you’re a life saver!

Excellent instructional videos .

I partially rebuilt the chassis and gearboxes to reduce the cracking noise when fourth gear in high range was selected and it’s reduced substantially . However , the cracking is partially due to the high resistance which naturally occurs in high gear. I found that this could be further reduced by treating the gears and axles with silicon spray.

Hi, The front wheels do not react on the steering wheel.

Please advise.

Thanks!

You have to follow all gears and axles between the steering wheel and the front axle to see where the disconnect is, but for that it is better to remove the front section of the body.

The #11 gray cross bars are 1/2 inch too long to fit on the luggage rack. I will try to cut before going to LEGO for shorter ones. I think the only thing I have to cut them are diagonals, not sure if that will work.

What do you recommend for cutting straight pieces neatly? Page 457 shows them short, but mine are past the opposite side by 1/4 inch. Still awaiting 2 pieces that were missing in bags #1 and #2(first time ever missing a LEGO piece).

That #11 axle should fit there, you definitely shouldn’t cut it. Make sure your mounting points are aligned correctly and all the other parts are in the correct places.

I have the pieces layed out exactly like picture on page 457. My #11 plus ends extends 3/8” beyond red piece. Luckily I live 30 minutes from the LEGO store in Tukwila, south of Seattle. If the black elbow pieces were each 1/8 in longer the bars would fit. I still need the black piece that the #11 fit against, it should be here by next week, then I will go to the store.

Duh! I had the smaller gray pieces at the top instead of the black, I am so used to the pieces going all the way in, so I was surprised to see a gap. Now just need missing part to arrive. Thanks for your quick reply to my mistake, keep up the good work!

I recently finished this set. However my front wheels do not spin to the same direction. Left and right wheel are always spinning in the opposite direction which make the car unable to move. Rear wheels look OK. Also I spotted that the central axel does not spin at all(by spinning the wheels and manually spinning the axel). I tried manually spinning the central red differential, it moves my rear wheels, but not the central axel and front wheels. I spent hours troubleshooting and followed this instruction and examime all possible issue mentioned above but yet to find the cause. Any help will be appreciated.

Incredible website! Unfortunatelly I did not find my issue here. My car works properly in R mode and in N mode. But when in D mode (at any gear speed), the car is able to move forward around 20cm (8 inches) and then it gets really hard to move more. It seems that if I push more, something will break. I was wondering if the issue is in the gearbox or in the speed selector.

I’m sure it’s your gearbox.

Thank you! Step 3 messed me up!

Hi. The problem I have is that when I put my gear on HI or LO, after a few centimetres of movement my car starts cracking and stops. However, when it is not engaged and is in neutral, everything seems to be fine and there is no cracking. Does anyone have a solution for my problem?

In neutral the gearbox is bypassed, so there’s no cracking. Check the video and the suggestions listed.

There is resistance in the drive train. When I turn the gearbox manually it turns the fake engine and the wheels just fine with resistance because of where I’m driving the wheels from. But when pushing the wheels on the ground it turns the engine but at an extremely low speed. Turning it into higher gears and putting it in Hi does little to nothing to change the speed of the engine. I double checked the instructions and saw the set was build spot on yet when looking at videos of other people playing with the set the engine turns at a significantly higher speed than mine.

What if it is cracking wen it is in drive but on high and low gear selector?

New issue not addressed yet on this guide that I’d love your help with.

My differentials are all in place in the correct orientation and I’ve verified this with pics and videos from your build. However, my front wheels and rear wheels spin opposite directions. This is even though the differentials are already oriented correctly.

I know one of your guides explains this as being related to a differential installed incorrectly, but there is some other issue my build is having. Do you have any thoughts or insights here?

Many thanks for your help!!

I finished assembling the car and found one gear (#4640536) was left unused. I found the engine cylinders don’t move. I decided to disassemble my unit. So far I disassembled back to the step 260. When I rotate the gear (#4640536, the same gear that was left unused), the cylinders move. Any idea on where I made a mistake? Any suggestion will be highly appreciated.

Additional findings.

When I attach this front assembly to the middle assembly (I mean the one with shift lever), I found the pistons moved only when the shift was in Rear. They don’t move when the shift is in Drive. Should I reassemble the middle assembly? Any clues?

Anyway, no gear should be left unused, right?

I reassembled my Land Rover from scratch. This time all gears were used in the assembly. Now everything is working as designed. I would like to give my hearty thanks to Racingbrick. This site was extremely helpful during my work.

Pingback: Lego Defender – Camiel Schoonens